|

Glass Shell and Tube Heat Exchangers are of recent

development. These heat exchangers can be used for condensation of

vapours, vaporisation, cooling and heating of liquids.

The shell and tube heat exchangers are available in

various combinations of Glass/Metal/FRP in shell or headers. Glass

shells are constructed using standard glass components like pipe section,

tee, cross, etc. Metal shells are generally constructed of MS in one

piece.

Shell and tube heat exchanger consists of a cylindrical

shell which houses a glass tube bundle. Tubes are sealed with shell

with the help of PTFE tube sheets. Each tube is individually sealed

by 'O' ring in tube sheets at both ends. Baffles are provided in the

shell to maintain state of turbulence of fluid as well as to hold the

tubes.

Shell and tube heat exchangers have come out to be more

advance and beneficial for its following advantages :

- Bigger heat transfer area in one unit.

- Less pressure drop.

- Stuffing box sealing allows easy tube replacement.

- Less maintenance.

|

|

Technical information

All the shell and tube heat exchangers are

constructed with 12mm OD, 1.5mm thick glass

tubes. These tubes are arranged in triangular

pitch of 21mm. Baffles are provided with 30% cut

at a distance of approximately equal to inner diameter

of shell. Generally, PTFE baffles are used in

Glass shells and PP baffles in Metal shells.

Shell and tube heat exchanger can be

operated within a temperature range of ~ 40°C to

150°C on either side. However, differential

temperature should not exceed 120°C at any

point. All the Shell and tube heat exchangers

can be used predominantly under full vacuum, provided

differential pressure does not exceed 3 bar g.

The range of overall heat transfer

co-efficient in the Shell and tube heat exchangers are

considered as follows:

Condensation :

Water -

Water

: 600-900 Kcal/m² ,h, °C

Condensation : Water - Organic

solvents : 400-600 Kcal/m²

,h, °C

Evaporation

: Steam -

Water

: 500-900 Kcal/m² ,h, °C

Cooling

: Water -

Water

: 500-600 Kcal/m² ,h, °C

Cooling

: Water - Organic solvents

: 250-600 Kcal/m² ,h, °C

Cooling

: Water -

Oil

: 75-350 Kcal/m² ,h, °C

Cooling

: Water -

Air

: 25-250 Kcal/m² ,h, °C

|

| DN |

No.

of

Tubes |

Cross

section Cm² |

Max.

Operating Pressure |

Shell

Side |

Tube

Side |

Tube

Side |

Shell

Side |

| Glass |

Metal |

80

100

150

225

300 |

7

19

37

73

151 |

23

43

93

189

348 |

5

12

23

46

96 |

3.0

2.0

1.5

1.0

0.7 |

3.0

2.0

1.5

1.0

0.7 |

3.0

2.0

2.0

2.0

2.0 |

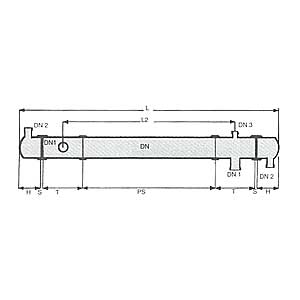

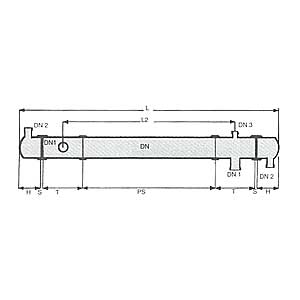

| Glass Shell |

|

|

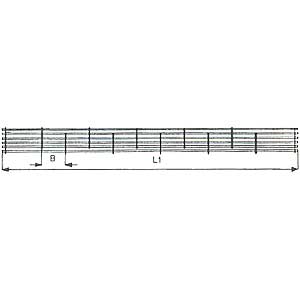

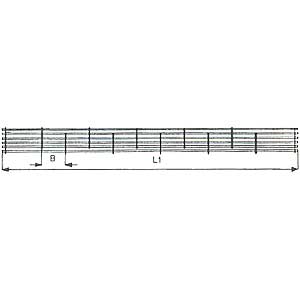

Cat.

Ref. |

HTAm² |

DN |

DN1 |

DN2 |

DN3 |

L |

L1 |

L2 |

PS |

T |

S |

H |

B |

Baffles |

RGG6/1

RGG6/1.5

RGG6/2

RGG6/3

RGG9/4

RGG9/5

RGG9/6

RGG12/8

RGG12/11

RGG12/14

RGG12/16

RGG12/22 |

1

1.5

2.2

2.9

4.1

5.2

6.6

8.5

10.8

13.7

16.5

22.2 |

150

150

150

150

225

225

225

300

300

300

300

300 |

50

50

80

80

80

100

100

100

150

150

150

150 |

25

25

50

50

50

80

80

80

80

80

80

80 |

25

25

50

50

25

50

50

25

50

50

50

50 |

1050

1400

1900

2400

1900

2300

2800

1950

2350

2850

3350

4350 |

800

1150

1650

2150

1550

1950

2450

1550

1950

2450

2950

3950 |

500

850

1300

1800

1200

1450

1950

1100

1450

1950

2450

3450 |

250

600

1000

1500

900

1000

1500

700

1000

1500

2000

3000 |

250

250

300

300

300

450

450

400

450

450

450

450 |

25

25

25

25

25

25

25

25

25

25

25

25 |

125

125

125

125

175

175

175

200

200

200

200

200 |

148

159

135

156

223

192

205

332

259

256

328

299 |

4

6

10

12

6

8

10

4

6

8

8

12 |

| Each Shell and

tube heat exchanger is supplied with following spares :

DN 150-5 tubes, 4 plugs, 4 brushes, 4 'O' rings, 1

key.

DN 225-10 tubes, 6 plugs, 6 brushes, 6 'O' rings, 1 key.

DN 300-15 tubes, 8 plugs, 8 brushes, 8 'O' rings, 1 key.

Orientation of branches, if other than above, should

be specified in order.

Following accessories are recommended to use with

Shell and tube heat exchanger :

- PTFE bellows on all nozzles.

- Pressure relief valve.

- Supporting clamps. |

|

|

|