|

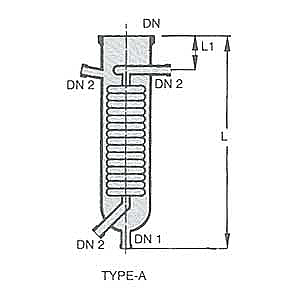

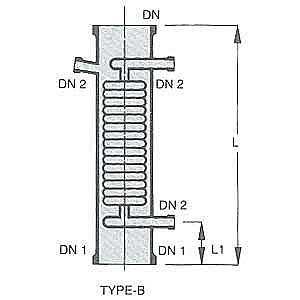

Boilers are used for vaporization of

liquids by passing the steam in the coils.

Boilers are made by fusing number of parallel coils in

a glass shell. In Boilers, coils are designed to

provide bigger cross section in the shell side as

compared to condensers.

The average heat transfer in Boilers is considered as

350 Kcal/m² ,hr, °C at a steam pressure of 3.5 bar.

|

Cat.

Ref. |

DN |

DN1 |

DN2 |

L |

L1 |

Type |

Actual

H.T.A.

m² |

Free

Cross

Area

Cm² |

Jacketed

Cap.

Litre |

HEB4

HEB4/4

HEB6

HEB6/6

HEB9

HEB9/9

HEB12/12 |

100

100

150

150

225

225

300 |

25

100

40

150

40

225

300 |

25

25

25

25

25

25

25 |

375

400

450

500

700

700

700 |

100

100

100

100

100

100

125 |

A

B

A

B

A

B

B |

0.15

0.15

0.35

0.35

1.00

1.00

1.30 |

40

40

50

50

150

180

330 |

2

3

5

7

16

20

40 |

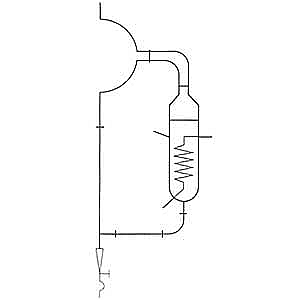

Notes on use of Boilers:

- Steam should be passed in the coils at a maximum

pressure of 3.5 bar which is equalant to a temperature

of 147°C.

- For higher temperature (maximum up to 200°C) heat

transfer fluids can be passed in the coils. ~ Cold

liquids

- Cold liquids should be preheated for better results.

- Boilers should be mounted in an external circulatory

loop (as shown in figure) and not direct at the bottom

of flask or column.

- Under certain circumstances, boilers can be mounted in

series to provide larger heat transfer area. |

|

|