|

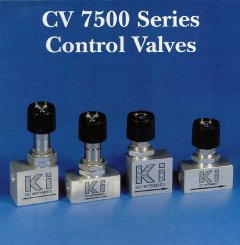

ARS offers control valves for low flow OEM, laboratory instrumentation,

or bench top flow control purposes. The valve designs and materials make

them suitable for use with a variety of gases and fluids.

ARS offers control valves for low flow OEM, laboratory instrumentation,

or bench top flow control purposes. The valve designs and materials make

them suitable for use with a variety of gases and fluids.

|

Valve Design Features

-

All designs

are panel mountable

-

Interchangeable needle tapers

-

Positive

shutoff

-

316

Stainless Steel or Brass

-

Straight

though (180º) or right angle (90º) flow paths

-

Flow ranges

from 5 CCM to 68 LPM of air

-

Standard

valve 10 turns full open

-

Precision

valve 16 turns full open

|

|

|

MAXIMUM FLOW CAPACITIES: |

|

Model |

Taper |

Max Flow

CCM Air |

Max Flow

CCM Water |

CV |

|

CVS

CVS

CVS |

1

2

3 |

13,000

46,000

68,000 |

760

2,150

3,550 |

0.0320

0.0912

0.1653 |

|

CVP

CVP

CVP

CVP

CVP

CVP |

1

2

3

4

5

6 |

253

470

1,100

3,800

11,900

21,300 |

17

28

74

219

722

1,255 |

0.0006

0.0011

0.0029

0.0110

0.0328

0.0494 |

Complete valves are available in straight through or 90º angle body

configurations and are constructed of brass or stainless steel. All

valves are supplied with 1/8" FNPT inlet and outlet ports. The valve

cartridge may also be integrally mounted in flowmeter assemblies. The

economical cartridge valve (CVS) is available in three different needle

tapers which cover our entire flow range. These units have a rising stem

and provide ten turns from closed to full open.

Complete valves are available in straight through or 90º angle body

configurations and are constructed of brass or stainless steel. All

valves are supplied with 1/8" FNPT inlet and outlet ports. The valve

cartridge may also be integrally mounted in flowmeter assemblies. The

economical cartridge valve (CVS) is available in three different needle

tapers which cover our entire flow range. These units have a rising stem

and provide ten turns from closed to full open.

The non-rising stem precision control valve (CVP) is available in six

different needle tapers, for fine control of very low flows. This valve

offers sixteen turns from closed to full open. Its design eliminates

saw-toothing and is virtually hysteresis free. All materials are matched

for similar coefficients of expansion.

The non-rising stem precision control valve (CVP) is available in six

different needle tapers, for fine control of very low flows. This valve

offers sixteen turns from closed to full open. Its design eliminates

saw-toothing and is virtually hysteresis free. All materials are matched

for similar coefficients of expansion. |